Application

It is mainly suitable for the drilling process of connecting plates, anchor plates, rib plates and other plates in steel structure industry

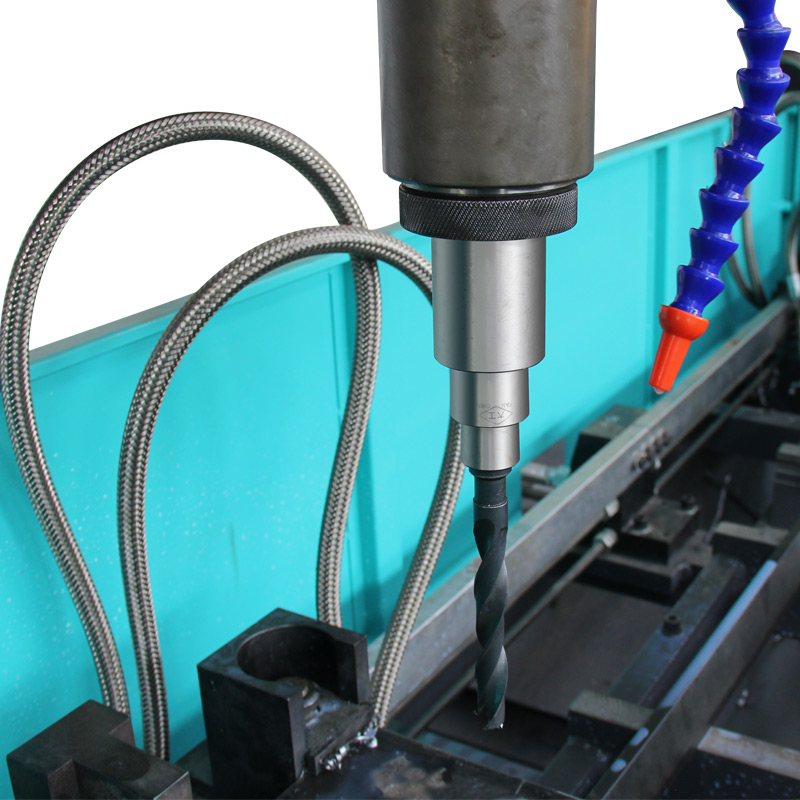

Composition: It is composed of bed, gantry, power head, and water circulation cooling system, chip removal system, hydraulic system, and CNC system.

Parameters:

Processing one piece: 2000*1600mm

Two pieces 1000*1600mm

Four pieces 1000*800mm

Stacking thickness: 100mm

Power Main motor 5.5kw

Feed stroke 180mm

Speed 120-560r/min

Drilling diameter 12-50mm

Drilling accuracy plus or minus 0.5mm

Equipped with 12 hydraulic clamps (clamping force 7.5kn)

Configuration of important parts guide wire cylinder

Hydraulic valve (Italy)

PLC

Advantages:

1. It is three times efficiency of traditional radial drills

2. Drawings can be imported directly through PLC without manual marking and positioning.

3. It is divided into four areas A B C D, when AB area is working, CD area can be loaded and unloaded, and the power head is in working state, while traditional radial drill needs manual marking and positioning when loading and unloading workpiece, the drill is in stopped state.

4. Our plate drilling machine is equipped with quick-change chucks, which can quickly change drill bits, while traditional drills need to be manually beaten with a hammer to replace the drill heads, resulting in deformation of the spindle and decreased accuracy. 5. 5.The plate drilling machine is hydraulic feed mode, which can feed quickly, automatically rotate and tap, and it is fast return, because the chain type chip removal can automatically recover waste chips into the chip removal box;

6. The cooling water can be recycled in the water circulation cooling method, so it is more environmentally and friendly.

High Speed CNC Three-Dimensional Drilling Machine

Application:

It is mainly suitable for steel structure industries such as high-rise buildings, bridges, power station boilers, offshore oil drilling platforms, etc., especially ,It is used in the three-sided drilling process of H beam steel, channel steel and other profiles.

Composition:

It is composed of bed, CNC sliding table, drilling spindle box (power head), and side pressing device, trolley feeding mechanism, hydraulic system, Steam and mist cooling system, chip removal system, numerical control system, feeding rollers.

Parameters:

150*80mm—1250*600mm

Length: 12m/15m

Automatic processing of loading and unloading materials: not less than 3m length

Spindle power: 15kw

Use BT40 spindle, convertible M4 (twist drill)

When using BT40 high-speed drill, it is cooled by internal cooling vapor mist, which requires air pressure at 0.5 MPa; when using M4 twist drills, use external cooling method,

Feeding speed 5m/min

Positioning speed 10m/min

Spindle speed 30-3000r/min

Drilling diameter 8-40mm

Drilling accuracy plus or minus 0.5 (over 10m plus or minus 1)

Motor power of trolley: 5kw

Feeding speed: 20m/min

Feeding weight: 6 tons (can add power roller up to 10 tons)

Advantages:

Main machine weighs 20 tons, the rigidity is strong, and the service life of drill bit is prolonged. As it is high-speed drill, it is three times efficiency of general drilling machine.

The trolley adopts servo feeding to improve feeding accuracy.

Software advantage:

It can directly transfer the processing procedure through TEKLA three-dimensional software DSTV file, and Kasry control system control three power heads for processing work piece.

With automatic alarm display, automatic fault diagnosis functions (when the code is entered manually error, machine stops working and alarm)

It can be programmed on line and off line, three-dimensional graphics preview, and humanized interaction and simple operation greatly improve production efficiency.

Corporate Headquarters:

2477 Qizhou Road, Jinan, P.R.China