CNC plate drilling machine is a high-efficiency plate drilling machine. This machine mainly consists of worktable, gantry frame , drilling power head, automatic chip removal and circulation cooling system, control system,longitudinal slide platform, hydraulic system, and a quick-change chuck.

Product Description

CNC Drilling Machine for Steel Profile Drilling Machine for Metal Plate CNC

Machine Composition and Characteristics

CNC plate drilling machine is a high-efficiency plate drilling machine. This machine mainly consists of worktable, gantry frame , drilling power head, automatic chip removal and circulation cooling system, control system,longitudinal slide platform, hydraulic system, and a quick-change chuck.

The processing area is divided into ABCD four processing areas, which can drill while loading and unloading workpieces at the same time,and it can also programe while drilling workpieces.

It has the characteristics of high precision, high efficiency, high rigidity, high reliability, etc.

Machine Application

It is widely used for steel structure,bridge,power communication towers , boiler brackets of thermal stations and other industries connecting plate , foundation plates ,end plates ,flanges ,structure plates ,and other parts drilling process .

The accuracy of the processed components meets the national standard "Code for Construction Quality Acceptance of Steel Structures" (No. GB50205-2001).

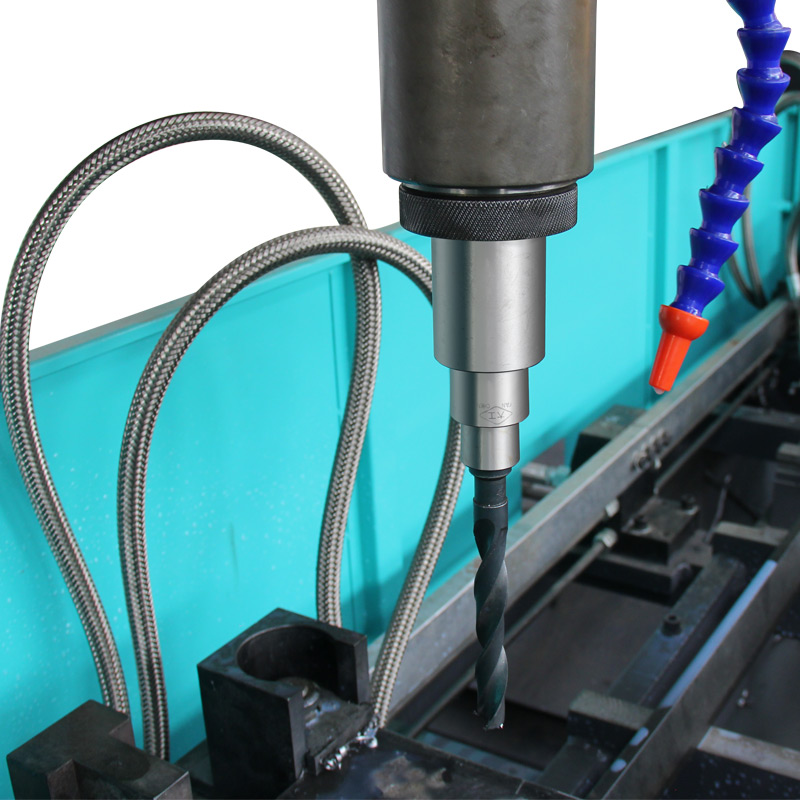

Product Details

Product Paramenters

Product Advantages

1.High work efficiency

This machine adopts the form of fixed bed and mobile gantry. Workpieces are clamped by hydraulic clamps, and the operator is controlled by a foot switch, which is easy to operate and saves labor. Small workpieces can be clamped at the four areas of worktable, which can significantly shorten production preparation cycle and improve production efficiency.

2 3 CNC axes,

Each CNC axis is guided by precision linear rolling guide, AC motor + ball screw drive

3.High working reliability

The upper computer automatically processes the starting and ending points of working feed , and can not only drill through holes,but also drill blind holes, stepped holes, and chamfered hole ends. It has high processing efficiency, high reliability, simple structure, and low maintenance costs.

4.Self-controlled stroke power head

High-efficiency self-controlled stroke drilling power head ,no need manually set the drill length and workpiece thickness, and can automatically perform fast forward-industrial advance-rewind for easy operation

5.Circulating water cooling

Forced water cooling for drill bit cooling

6.Automatic chip removal

Chip remover is installed under the bed, which can automatically remove chips

7.Automatic lubrication system

Reduce equipment wear and increase service life

8.Less failures

Main components ,such as ball screw , linear rolling guide , hydraulic parts , electrical system , servo motor and frequency

converter are all of world famous which are more steady and credible .

Corporate Headquarters:

2477 Qizhou Road, Jinan, P.R.China